Gamma Scanner: A modular Drum Measurement System

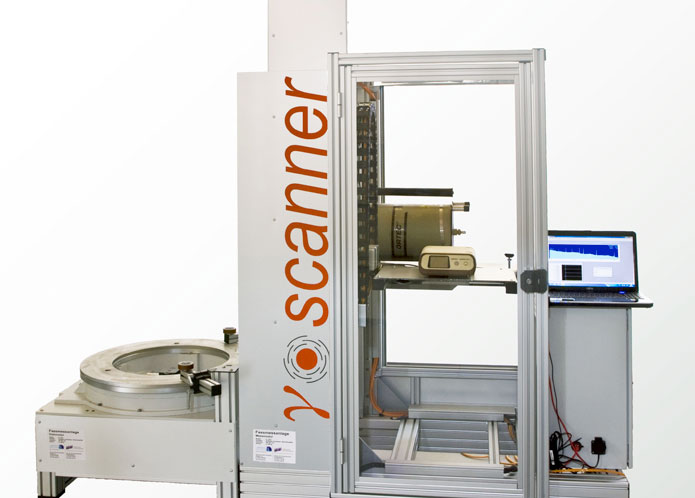

If you want to know what's inside a drum without opening it, you need good ideas. Lots of them went into the development of Marschelke Messtechnik's drum measurement system, Gamma Scanner. The system is designed in a modular manner, is easy to transport and doesn't require complex wiring. That saves time and money for doing business.

The Gamma Scanner is designed as a modular complete system to measure and inspect drums filled with radioactive waste. Scanner and software have been developed jointly with the Jülich Research Center, which was also the certifying agency.

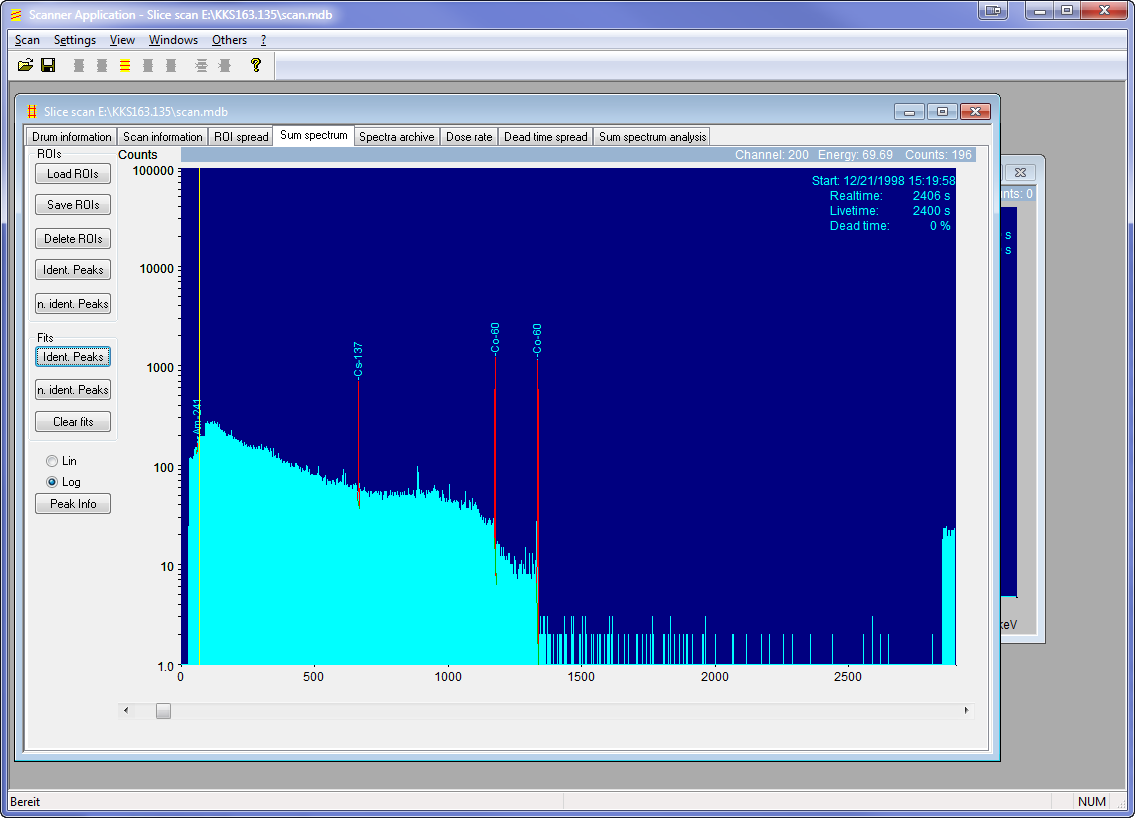

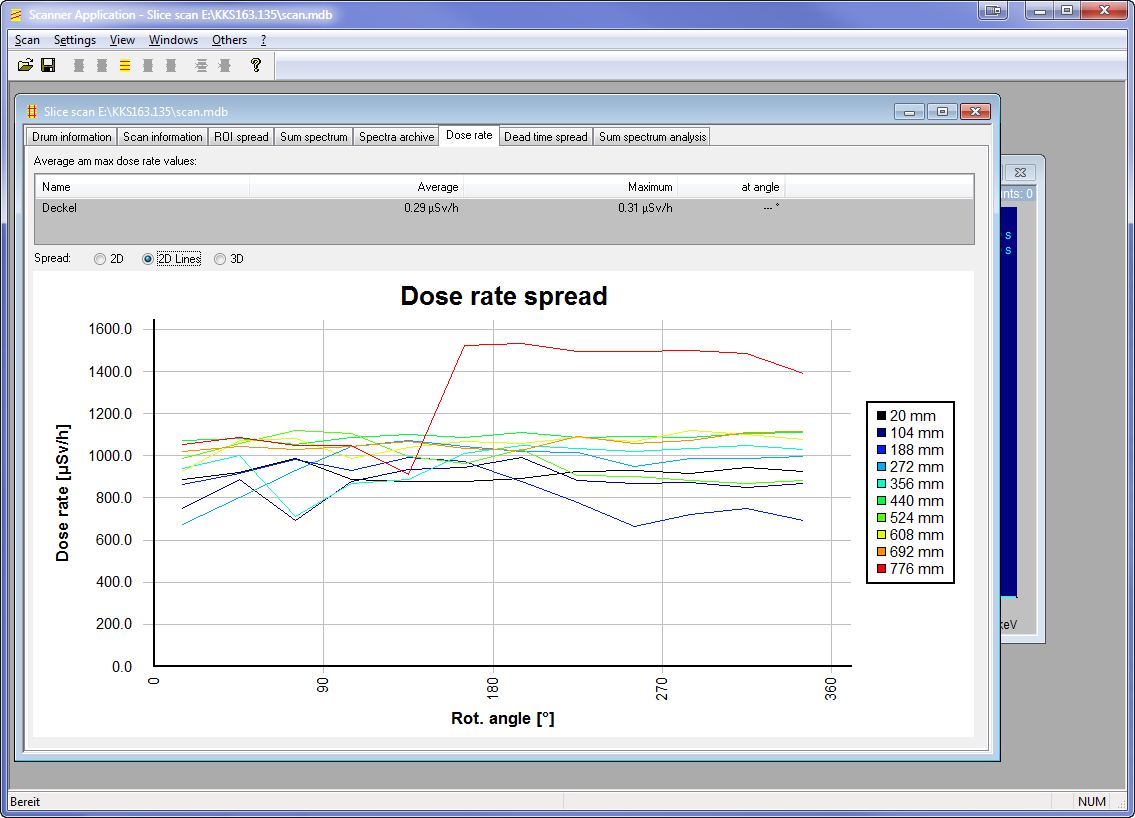

With gamma spectrometry, dose rate monitoring and a scale, the drum inspection system is the perfect tool to determine a drum's nuclear interior. Also, the Gamma Scanner is extremely flexible, as the system consist of two easy to separate and transport modules. Both the rotating and vertical modules can be moved by a forklift or a lifting car. The modules can be taken apart by separating three plug-in connections.

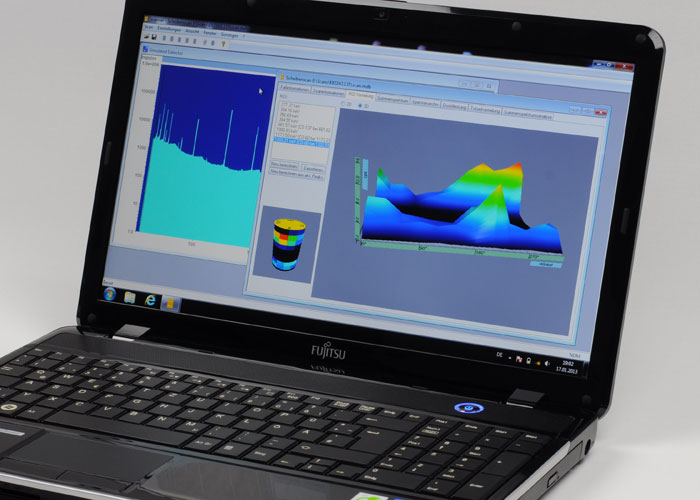

Aluminum is used to build the measurement system which therefore is rather light in weight. The Gamma Scanner can be connected to a standard 230-voltage-electrical outlet. The three-phase power connector is not necessary, neither is a specific computer hardware, as the measurement data will be transmitted to a common Windows PC or laptop by a LAN connection.

The detector lifting platform can be stocked with various materials. Nitrogen or electronically cooled germanium detectors with client specific collimation and shielding are one option, as are other measurement systems. Marschelke Messtechnik is a one-stop-shop for the Gamma Scanner: We oversee the planning and delivery of all components by the manufacturer, as well as the operation launch on-site.

|